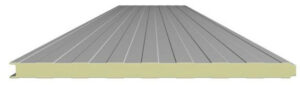

Rigid polyurethane foam, sandwiched by metal or flexible facings, is increasingly successful in meeting the requirements of the construction industry, emphasizing on cost effective system building and energy conversation. Their specific file of application covers the construction of industrial and commercial buildings, ware houses and cold storages, refrigerated transportation).

Polyurethanes are three dimensionally networked macro cellular thermosets as a result of a reaction between a multifunctional polyol and a multifunctional isocyamnate/MDI in the presence of a blowing agent and additives. Apt metals can supply sandwich panels in various thickness (35mm to 100mm), various facing combinations of pre painted steel and aluminium in thickness ranging from 0.25mm to 1.0mm and in different colors.

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable.

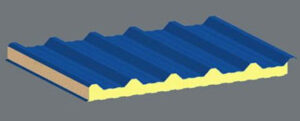

APTSP 35/200

Applications

- Roof and wall Panel

Specification

- Aluminum profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

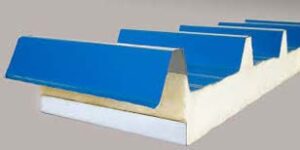

APTSP 45/250

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

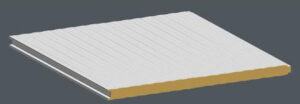

APTSP 25/253

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

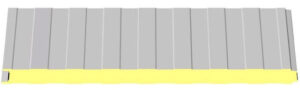

APTSP 38/200

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

APTSP 20/200

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

APTSP 45/150

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

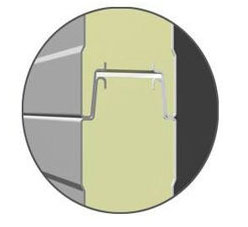

Flat/Wall Sandwich Panel

Life of Our PUR Sandwich Panel for Roofing and Cladding Purpose

The longevity of sandwich panels depends on the construction. Choose the appropriate technical specification of the product components according to the needs of the building, environment, and climatic conditions in which it is located.

Benefits of our PUR/PIR Sandwich Panels in UAE

Easy Installation

The assembly of the sandwich panels is very easy with just a few joints on wide surfaces. With advanced transportation options and mechanical lifting devices significantly, you can also reduce transportation and coating times. Therefore, your project will be delivered in a short time, saving you time.

Good Thermal Resistance

The sandwich panel offers high thermal insulation due to PUR/PIR material. Thermal insulation with PUR sandwich panels prevents problems such as mold and moisture caused by thermal movement and condensation, ensuring the robustness and longevity of your building.

Saves your Long-term Cost

The lightness of sandwich panels allows you to get advantages in terms of transportation and main construction costs. In addition, the maintenance costs are low due to its durable structure.

In short, the sandwich panel is a quick, aesthetic, and economical solution due to its durability.

Provide Building an Aesthetic Appearance

The perspective of your building is like the mirror of your dreams. That’s why every day we add new ideas for the aesthetics of your buildings to our sandwich panels. You can liven up the exterior walls of your building and get an aesthetic look by designing the sandwich panels in different colors and in a structure that allows them to be placed horizontally, vertically, or at an angle.

Due to its property of being used in the interior sections, the sandwich panels allow you to create different designs.

Water and Air Tightness

With a waterproof structure, the sandwich panels guarantee active hydro-insulation against natural agents such as snow and rain. This will prevent moisture and mold. By preventing corrosion of load-bearing structures, they ensure a healthy and comfortable environment in your building. A building becomes stronger and more durable.

Want Rockwool Sandwich panel for roofing and cladding purpose?

Searching for Acoustic Sandwich Panel Supplier in UAE?

Want PIR boards in UAE?

Looking for a Flat Panel for wall & partition supplier?

All these questions have one answer; APT Metals.