Sandwich Panels – PUF, PIR, Rockwool

Rigid polyurethane foam, sandwiched by metal or flexible facings, is increasingly successful in meeting the requirements of the construction industry, emphasizing on cost effective system building and energy conversation. Their specific file of application covers the construction of industrial and commercial buildings, ware houses and cold storages, refrigerated transportation).

Polyurethanes are three dimensionally networked macro cellular thermosets as a result of a reaction between a multifunctional polyol and a multifunctional isocyamnate/MDI in the presence of a blowing agent and additives. Apt metals can supply sandwich panels in various thickness (35mm to 100mm), various facing combinations of pre painted steel and aluminium in thickness ranging from 0.25mm to 1.0mm and in different colors.

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 – H16 Temper from tension leveled coils – different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc – Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse – PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable.

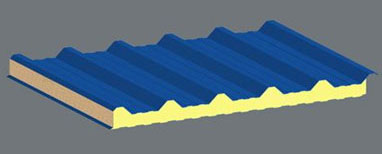

APTSP 35/200

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

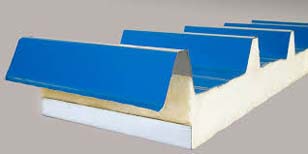

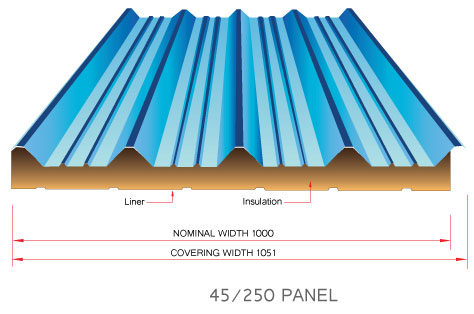

APTSP 45/250

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

APTSP 25/253

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

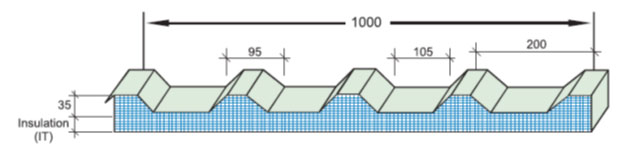

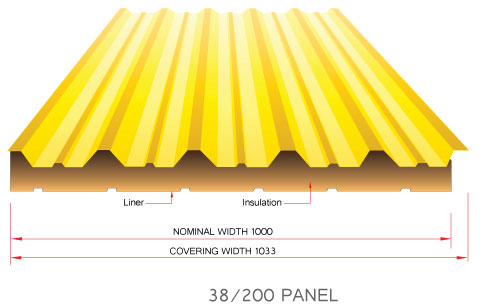

APTSP 38/200

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

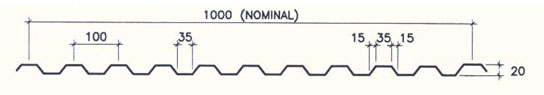

APTSP 20/200

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

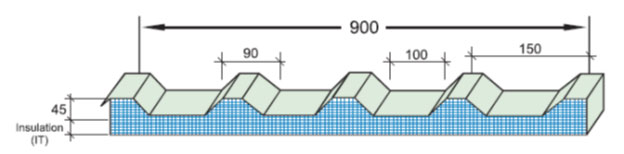

APTSP 45/150

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable

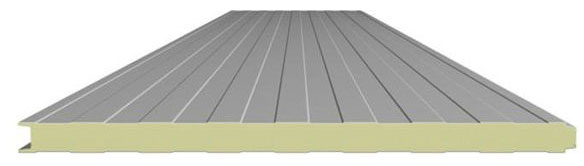

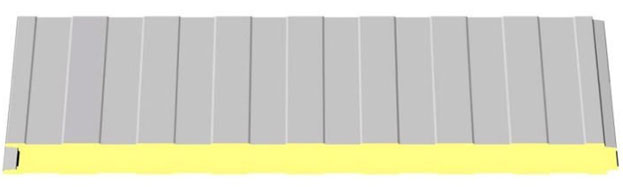

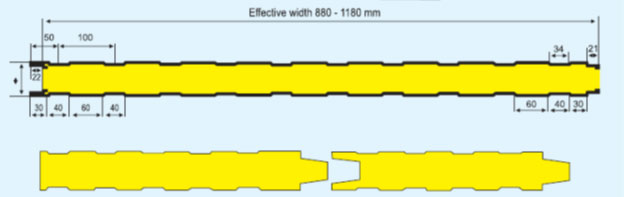

Flat/Wall Sandwich Panel

Applications

- Roof and wall Panel

Specification

- Aluminium profiled sheet is 0.5 mm. up to 0.9 mm. thick Alloy A3105 - H16 Temper from tension leveled coils - different Alloy can be supplied on request.

- GI & Alu Zinc coated steel profile sheets 0.5 to 0.9 mm thick as per ASTM A 656 for GI & ASTM A 792 for Alu Zinc - Different grades Can be supplied on request

- Painting is baked regular modified enamel polyester, with 5 micron primer and 20 micron coat on the weathering side and 5/7 micron primer on the reverse - PVDF, Silicon, Modified Polyester, Platisol & ARS coating on request is applicable